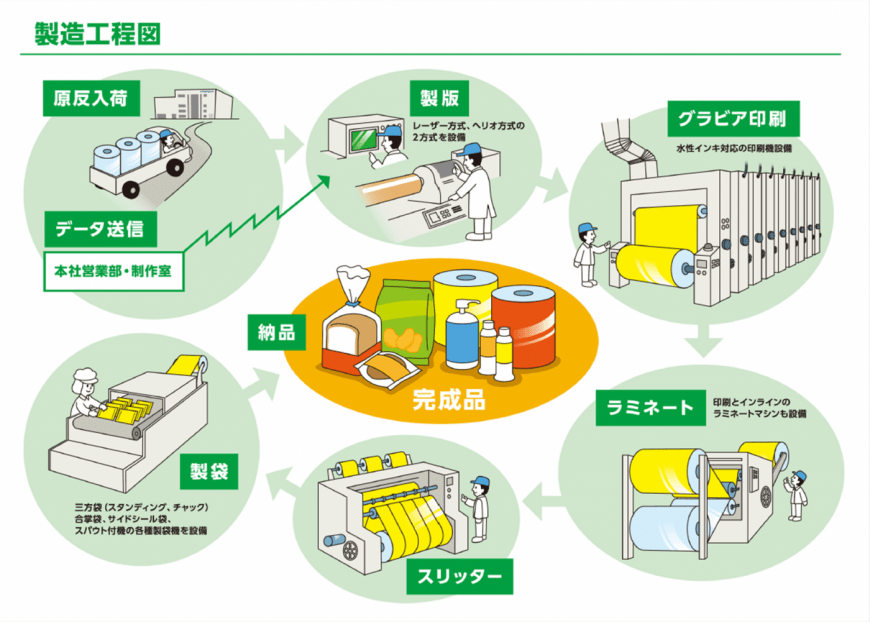

Speedy Delivery/Integrated Internal Production System

In addition to many years of experience trained by daily delivery users with short delivery times, the two Saitama factories, which have their own design, plate making and delivery departments, and are the mainstays, carry out all processes from the printing process to the bag making process. It can be completed in the same factory.

This integrated internal production system allowed us to realize smooth processing and timely delivery.

In addition, by connecting in-house production systems nationwide and managing production collectively, we will select the machine with the best processing timing.

In addition, by connecting in-house production systems nationwide and managing production collectively, we will select the machine with the best processing timing.

Stable and High-level Quality Control

Factory Quality Control System

We are always trying to manufacture and sell stable quality products by improving various defective product generation prevention know-how and equipment unique to Kanaoka, which we have cultivated since our establishment in 1951.

In addition to inspections within each manufacturing process, we also perform out-of-process inspections by the inspection section, and only products that meet the passing standards are provided.

In addition to inspections within each manufacturing process, we also perform out-of-process inspections by the inspection section, and only products that meet the passing standards are provided.

Through these, we have built a stable product supply system with few complaints.

In addition, the traceability mechanism that allows us to trace back from the product to the raw materials used makes it possible to promptly check and respond in the unlikely event of a problem.

In addition, the traceability mechanism that allows us to trace back from the product to the raw materials used makes it possible to promptly check and respond in the unlikely event of a problem.

Obtained FSSC/ISO Certification

FSSC22000 | International standard for food safety management system |

ISO9001 | International standard for quality and safety management system |

ISO14001 | International standard for environmental management system |

Details of each certification / certification are described below.

Clean factory with thorough hygiene management

Hygiene management is the most important item for factories that manufacture packaging materials that come into direct contact with food.

Kanaoka maintains initiatives towards hygiene management equivalent to that of a factory in a major food company.

"Packages are also part of food products." Based on this belief, we are constantly striving to improve every day, aiming for the same perspective and standards as food manufacturers through regular audits by food manufacturers and internal audits by our own companies.

In particular, the 2 main Saitama factories are leading the industry by obtaining FSSC22000 certification.

Incorporating food defense methods, we are always trying to manufacture and sell safe and secure products for our customers.

Furthermore, we measure invisible fine suspended matter in the manufacturing room every month with a particle counter, and strive to maintain and maintain a clean environment at all times.

In addition, we also measure floating fallen bacteria in-house every quarter.

Furthermore, we measure invisible fine suspended matter in the manufacturing room every month with a particle counter, and strive to maintain and maintain a clean environment at all times.

In addition, we also measure floating fallen bacteria in-house every quarter.

As a result, we maintain the industry's top class hygiene.

Food safety policy

1. Kanaoka will comply with legal and regulatory requirements and prevent the occurrence of food safety hazards.

2. Kanaoka contributes to the safety of the entire industry by providing safe food packaging and information.

3. Kanaoka reviews the adequacy of the food safety system every year and will continue to improve it.

4. At Kanaoka, we all understand our food safety policy, follow the rules, and provide our customers with safety and security.

6S

Usually as the basis of "manufacturing," "5S" is said to be important, but

Kanaoka maintains initiatives towards "Safety takes precedence over everything". Based on this idea, we promote

"6S© Kanaoka" actions.

6S = safety, organization (seiri), tidying up (seiton), cleaning (seisou), cleanliness (seiketsu), discipline (shitsuke)